High performance liquid chromatography in food safety detection work has an irreplaceable role. The author combined years of work experience and drew reference to the work of peer thinking, etc., from the user’s perspective of high performance liquid chromatography, the purchase of instruments, installation and commissioning, use, maintenance, and other aspects of its “life” to talk about.

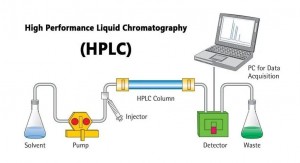

High performance liquid chromatography is one of the most commonly used instruments in analytical testing. It can be used for the simultaneous detection of multiple components in a sample or the individual detection of certain components. The detectors used in HPLC are mainly ultraviolet detectors, diode array detectors, differential detectors, fluorescence detectors, evaporative light scattering detectors, and mass spectrometry detectors, which are widely used in the analysis work of various industries.

Purchasing a High Performance Liquid Chromatograph

Before purchasing an HPLC instrument, the first thing to do is to determine the amount of the purchasing budget, what testing projects you want to carry out with the instrument, the number of samples to be tested, the requirements for testing efficiency, etc., and then determine the configuration of the HPLC instrument to be purchased, such as the choice of manual or automatic injector, the number of bits of the autosampler inlet tray, the type of detector, and whether you need to purchase an ultra-high performance liquid chromatograph, etc.

Secondly, the market coverage, advantages and disadvantages, after-sales service efficiency, and quality of different manufacturers and models of HPLC in the market should be investigated, and the cost-effective HPLC instrument should be selected.

Installation and commissioning of HPLC instruments

Each high performance liquid chromatograph purchased by the inspection and testing organization should be designated to interface with the installation engineer before installation to confirm the installation environment of the instrument, facilities, reagents required for installation and commissioning, etc., and prepare the relevant environmental facilities and reagents as required.

After preparation, confirm the installation time with the engineer and carry out the installation and commissioning work at the agreed time. During this period, it is recommended that a dedicated person works with the installation engineer to provide support and confirm the content and results of the installation and commissioning to ensure that the instrument’s performance is normal and meets the requirements.

Management of high performance liquid chromatography

1, The establishment of instrument archives testing institutions should arrange for a dedicated person to the instrument to establish archives. The establishment of the file facilitates moving the instrument, software failures, changes in the personnel of the testing institution, reinstallation of the operating software, and inquiries about record materials.

The file should be as much as possible to collect and collate information related to the instrument, such as instrument manuals, installation disks, instrument maintenance records, instrument verification and calibration certificates, etc.; the registration of instrument use and instrument maintenance and repair records generated during subsequent use should also be regularly collated and filed in the file.

2, Set login accounts and permissions for testing institutions according to the purpose of laboratory personnel use of instruments. Different personnel set login accounts and passwords, and their permissions are limited to avoid the improper operation or malicious behavior, resulting in the loss of testing institutions’ files and other unnecessary situations.

3, Good instrument identification testing institutions should prepare a unique identification number for each instrument and equipment and management of the instrument’s status to prompt the user on what state the instrument is currently in and whether it can be used normally.

The use of high performance liquid chromatography

1, Instrument calibration and confirmation of testing institutions if the use of high performance liquid chromatography to carry out testing projects and test reports with proof should be in the official use of the instrument before the qualified metrology department for its certification to be certified by the certification certificate, the validity of the certification and instrument performance to meet the needs of the institution to carry out the sensitivity of the test project, and then start approval. Approval is completed before use.

2, Do a good job in the use of personnel training testing institutions can be based on the proportion of institutional instruments and personnel, reasonable arrangements for the use of instruments, if you can be dedicated to the protection of the instrument is optimal, if not, you can develop several people to share a. According to the use of personal experience and ability of personnel and other circumstances, the use of instruments before the corresponding training, specific operations can be arranged for an experienced teacher to supervise and guide from the side until the use of personnel can be carried out independently.

3. Establish a register of use, maintenance and repair records, etc. The register and records can be in paper or electronic form—record who carried out, when, what project testing, or what repair and maintenance work.

4, The use of precautions:

(1) High performance liquid chromatography in food sampling work mainly uses reversed-phase chromatography but occasionally also uses normal-phase chromatography, so the user must confirm the current system is in which chromatographic state before use;

(2) The mobile phase system, injector, etc., exhaust operation to avoid bubble interference; formal injection before setting the mobile phase, HPLC column, detector, etc.

(3) The sample to be tested must be clarified and transparent according to the requirements of the instrument and can be purified by high-speed centrifugation or filter membrane;

(4) The order of injection is recommended to follow the order of reagent blank, standard series solution, reagent blank, sample blank, quality control sample, sample to be tested, and reagent blank to confirm whether there are substances in the instrument that interfere with the components to be tested, the quality control effect, etc. Suppose there are more samples to be tested. In that case, it is recommended to insert the quality control sample in the middle of the sample to be tested to ensure the quality of the detection;

(5) When using gradient elution conditions for detection, after the detection of one sample is completed, make sure that the column pressure and other conditions are restored to the initial state before carrying out the detection of the next sample;

(6) After all the detection work is completed, The reversed-phase system is recommended to be preserved in methanol or acetonitrile, including the injector and the liquid-phase pipeline part. If buffered salt is used as the mobile phase, the salt should be flushed out with a large proportion of the aqueous phase and replaced with the pure organic phase.

Maintenance of High Performance Liquid Chromatography

The frequency and items to be verified can be based on the frequency of use of the instrument and the testing items to ensure that the instrument is in normal condition during use.

According to the different failure-prone situations of the instrument, regular maintenance is carried out on key parts of the instrument, such as the mobile phase system (e.g., flow path inlet end filter, reservoir bottle), injection system (e.g., injection needle, injection needle holder, injector), waste liquid (waste liquid is regularly disposed of and released for volatilization), etc.

The HPLC is like our body, and the parts work together. In practice, it is important to care for the instrument as we care for our body. Pay close attention to the subtle changes in the instrument, such as the sound of the pump running, the change of the column pressure under isocratic conditions, the change of the retention time of the same detection component under the same conditions, etc. Through these conditions, we can judge whether the state of the instrument has changed and whether there is a need for maintenance or repair. Only in this way will the instrument remain in good condition and ensure smooth operation.

Post time: Jan-14-2023