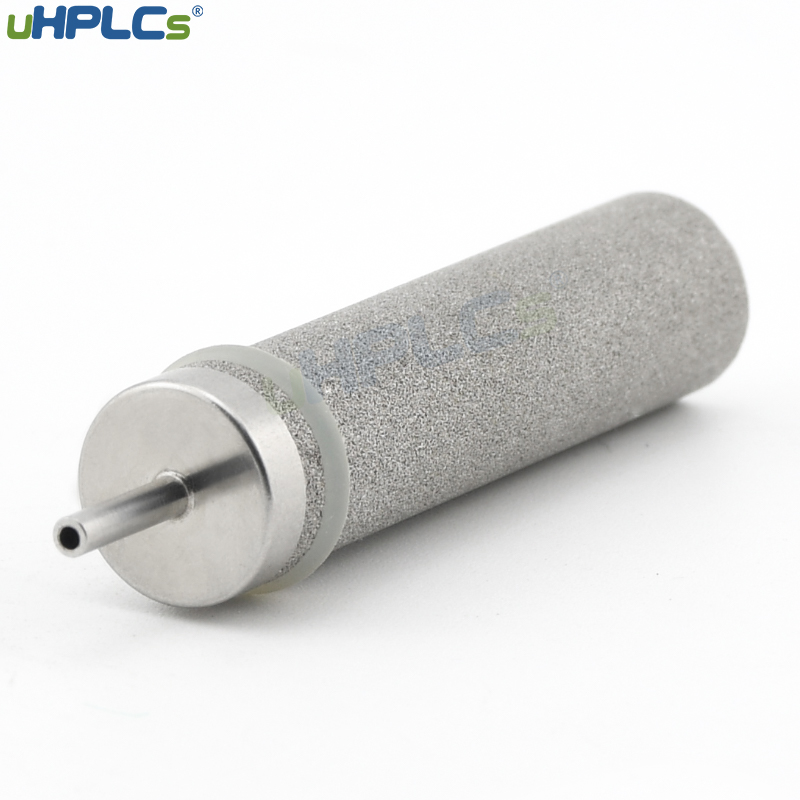

Inlet Solvent Filters

Why Use An Inlet Solvent Filter?

Filter out particulate matter from solvents to avoid damage to expensive hardware. (Use a 10 µm or 20 µm solvent filter version for this purpose. Solvent inlet filters for analysis liquid phases PCTFE / PEEK connectors 5 mm/3.2 mm, stainless steel solvent inlet filters 12-14 µm pore size; Inlet Solvent Filters for preparative liquid phases: PCTFE / PEEK connectors 7mm/4mm, stainless steel filter heads 20-30µm pore size. uHPLCs solvent filters have an added “none bubble” feature to help to use up the solvent in the solvent bottle to the maximum extent.)

To prevent particulates from the sparging system from entering the mobile phase reservoir and to help disperse the sparging gas efficiently. (Use a 2 µm solvent filter for this purpose.)

Secure your tubing to the bottom of the bottle. (Most stainless steel filter options work best for this purpose).

Note: It is usually a good idea to change the inlet filter as part of your semi-annual or annual preventative maintenance program.

Stainless steel solvent inlet filters should be avoided if the mobile phase involves the following solvents: lithium iodide, potassium chloride, high concentrations of nitric acid and sulfuric acid. Organic acid solutions in organic solvents, such as 1% acetic acid in methanol, corrode stainless steel, carbon tetrachloride, and isopropanol or THF mixture.

FAQ

Do I need to filter the mobile phase before using it in liquid chromatography? What is the purpose of filtration?

(1) Organic reagents of chromatographic purity or higher can be used without filtration. Still, when using analytically pure organic reagents or buffer salts, they must be filtered because of their lack of purity or the possibility of crystallization.

(2) The main purpose of the mobile phase solvent filter is to protect the liquid phase system and to eliminate the influence of contamination on the analytical results. If not filtered, fine particles in the mobile phase will accelerate the clogging and wear of the inlet valve; they will also accelerate the wear of the plunger rod and sealing components.

(3) Filtration also removes air bubbles from the mobile phase to a certain extent and acts as a degasser.

What solvents should be avoided in stainless steel tubing in liquid phase systems?

(1) Alkali metal halides and their acid solutions (e.g., lithium iodide, potassium chloride, etc.) may corrode stainless steel.

(2) Avoid direct use of high concentrations of inorganic acids (such as sulphuric acid, nitric acid, etc.), especially at higher temperatures should be prohibited, and can be replaced by less corrosive phosphoric acid or phosphate buffer solution for stainless steel, etc.

(3) should avoid halogen-containing solvents or mixtures that can form free radicals or acids, as stainless steel plays a catalytic role for such substances, so the use of such substances will react in the stainless steel tubing.

(4) Ethers containing peroxides (e.g., tetrahydrofuran, dioxane, dipropyl monoethyl ether) should be filtered through the dry aluminum oxide to remove the peroxide first. Otherwise, direct use should be avoided.

(4) A mixture of carbon dioxide, isopropanol, or tetrahydrofuran will corrode stainless steel and should be avoided.

How do we prevent and deal with clogged solvent filters?

(1) Contaminated solvents or algae in the reservoir bottle can shorten the life of the solvent filter. Algae grow in the aqueous phase, especially in the pH range of 4 to 8, and buffering solvents (e.g., phosphate or acetate) can accelerate algae growth.

(2) Options to prevent clogging of solvent filters are.

①. use freshly prepared solvents, especially buffers, as far as possible, and filter the mobile phase accordingly using 0.2 μm filters where possible.

②. try not to use mobile phases that have been left for a long time; if they must be used, they should be re-filtered.

③. The solvent is recommended to be changed or refiltered every two days.

④. avoid exposing the reservoir bottle to direct sunlight.

⑤. if permitted, add a percentage of organic solvent or acid to the aqueous mobile phase as appropriate.

⑥. for mobile phases containing water, brown storage bottles are recommended.

Tip: Polarity of organic solvents

How do I maintain my liquid chromatography inlet solvent filters?

(1) When using water or buffer salts as the mobile phase, the mobile phase must be changed frequently, preferably daily or at least once every two days for water and ready-to-use for buffer salts. If the solvent is not changed in time, microorganisms can easily grow. It can affect the stability of the baseline and even clog the filter.

(2) To test if the solvent filter is clogged, the solvent filter can be pulled off. When the line is full of solvent, and the filter is not clogged, the hydrostatic effect will allow the solvent to flow normally from the filter. If the filter is clogged, no solvent or very little solvent will flow.

(3) When the solvent filter is blocked, ultrasonic cleaning is not recommended for solvent filters made of glass. Because ultrasonic is very statistical to destroy the glass filter plate, it is recommended to dilute nitric acid with a concentration of 35% and soak it for 1 hour, then wash the filter with pure water; stainless steel inlet solvent filter can be ultrasonically cleaned.

How do I solve the problem of air bubbles not draining at the solvent inlet filter?

(1) When different solvents are mixed, air bubbles are easily generated. If the solvent is not degassed, there will be many air bubbles in the mobile phase, so degassing can be carried out employing ultrasound, etc.

(2) If the solvent filter is contaminated and bubbles are generated, the filter can be cleaned or even replaced.

(3) The chromatography system pipeline is not well sealed, resulting in bubbles. If necessary, the instrument pipeline should be leak detected.

Have Any Questions for HPLC Inlet Solvent Filters, Or like to Know more details and Price, You are welcome to contact us by

email sales@uhplcslab.com , or you can fill the follow form to send us inquiry, we will send back to you within 24-hours.