As the Chinese New Year holiday approaches, while preparing to enjoy the long holiday, uHPLCs would like to remind all laboratories to prepare for the shutdown of the liquid phase mass spectrometer coupler and to make the necessary backups of important experimental data before shutting down the machine.

Waters chapter

I. Shutdown and deactivation operation

1. Flush the system, and stop the liquid phase will be used to flush the column following the flushing method. All liquid-phase pipelines are saved in methanol. If the method mobile phase contains salt, water transition and then replaced with methanol, methanol 0.4 mL/min flow rate flush for more than half an hour to ensure that each pipeline is flushed with methanol. Stop the flow rate and remove the seal protection from both ends of the column.

2. Stop the mass spectrometer first to confirm that the liquid phase flow rate has stopped, then standby the mass spectrometer, wait for the desolvation gas temperature to drop 100 °C below to turn off the nitrogen, clean the ion source and the inner cavity of the ion source. After ensuring cleanliness, vent the vacuum tune page > vacuum > vent >.

3. Sequential shutdown Please make sure to close the MassLynx software first -> then turn off the instrument power -> turn off the computer -> turn off the liquid nitrogen tank nitrogen main valve or nitrogen generator power -> turn off the argon main valve -> turn off the UPS uninterruptible power supply for mass spectrometry -> empty the buffer bottle liquid (if any) and the waste bottle.

II. Resume operation

1. Check the power supply and gas source

Ensure that the LC-MS and other instrument power cables are energized and connected to the UPS uninterruptible power supply. Observe that the pressure of the partial pressure gauge of the liquid nitrogen tank is between 0.5-0.7MPa and the argon gas is between 0.05-0.1MPa.

2. Turn on the air conditioner and check the waste pipe

Turn on the air conditioner and set the temperature to 20-22°C. If you are not in a hurry to use the instrument, keep the air conditioner running for 4-8 hours before turning on the instrument. Before turning on the instrument, please check the waste gas pipe to ensure that it is clear in case the exhaust gas is not discharged smoothly after the mass spectrometer is running normally and an error is reported.

3. Sequential power-up

Turn on the computer and enter the Windows interface. Turn on the injector, pump, and mass spectrometer in order. After the mass spectrometer has been powered on for 10 minutes, open the MassLynx software and evacuate overnight until the next day. After full filling of the liquid phase, rinse with methanol at a flow rate of 0.4 mL/min for more than half an hour and replace the mobile phase for normal use.

AB SCIEX Chapter

I. Shutdown and deactivation operations

1. Liquid phase shutdown procedure Liquid phase flow path flushing and shutdown procedure Firstly, flush the column thoroughly and save the column with methanol solvent. Remove the column, replace it with a two-way, disconnect the liquid phase into the ion source pipeline, replace the mobile phase with 50% methanol aqueous solution, flush with a flow rate of 0.4 mL/min for 60 min, replace the mobile phase and wash solution with 100% methanol, exhaust the mobile phase pipeline for 5 min, exhaust the autosampler pipeline for 25 min, flush the pipeline with a flow rate of 0.4 mL/min for 30 min, and stop the infusion of a liquid. Turn off the power to the liquid phase units.

2. Mass spectrometry shutdown procedure

Before the mass spectrometer is switched off, it must be maintained briefly to prevent dirt from being cleaned for a long time.

3200 series:

- Turn off the power to the main body of the mass spectrometer.

- Wait for about 30 min.

- Turn off the power to the mechanical pump.

- Turn off the nitrogen generator and turn off the computer.

4500 Series, 5500 Series:

- Press the Vent key for 5 seconds.

- Wait for about 30 min.

- Turn off the power to the main unit.

- Turn off the nitrogen generator and turn off the computer.

II. Resume operation

1. Check the power supply gas source to ensure that the LC-MS and other instrument power cables are energized and connected to the UPS uninterrupted power supply. Observe that the nitrogen generator is stable and has a three-way air pressure, as shown below.

2. Check the environment and pump oil to turn on the air conditioner and set the temperature to 20~22 ℃. If you are not in a hurry to use the instrument, keep the air conditioner running for 4~8 hours before turning on the instrument. Before turning on the instrument, please check the exhaust gas pipe to ensure that it is clear in case the exhaust gas is not discharged smoothly after the mass spectrometer is running normally and an error is reported. Check the quality and quantity of the pump oil. If the pump oil turns yellow and black and the quantity of oil is below the lower limit, please replace the pump oil in time.

3. Sequential power on the 3200 series: Turn on the power of the mechanical pump, wait for about one h, and turn on the power of the mass spectrometer mainframe. Activate the mass spectrometer, open the mass spectrometer icon at the bottom right corner of the software and observe the molecular pump and vacuum reading status to see if it is normally turned on. Evacuate overnight and observe the vacuum readings to reach the required vacuum level for the mass spectrometer before normal use.

4500 series: Turn on the power directly to the mass spectrometer mainframe. Activate the mass spectrometer, open the mass spectrometer icon at the bottom right corner of the software and observe the status of the molecular pump and vacuum readings to see if they are on properly. Evacuate overnight and observe the vacuum readings to reach the required vacuum level before normal use.

Open each liquid phase unit in turn and replace the mobile phase pipeline carrying the aqueous phase with ultrapure water, the needle wash pipeline with 50% methanol aqueous solution, and the plunger cleaning pipeline with 10% isopropanol aqueous solution. The mobile phase line was exhausted for 5 min, the autosampler line was exhausted for 25 min, and the flow path was flushed at a flow rate of 0.4 mL/min of 50% methanol aqueous solution for 60 min, the infusion was stopped and the column was installed and ready for use.

Shimadzu Chapter

I. Shutdown and deactivation operation

1. Simple maintenance operation to clean the liquid phase system before shutdown: remove the column after flushing, seal it with a plug and store it; replace the two passes, replace the mobile phase with 50% aqueous methanol and flush for 60 minutes at a flow rate of 0.4 mL/min; replace the mobile phase and needle wash solution with 100% methanol, vent the mobile phase line for 5 minutes, vent the autosampler line for 25 minutes and flush the line for 30 minutes at a flow rate of 0.4 mL/min. Flush the line for 30 minutes.

Clean the ion source:

- Scrub the inner cavity of the ion source with 50% methanol water.

- Scrub it again with pure methanol, not touching the spray needle.

- Remove the DL tube and sonicate it with 50% methanol water for 20 min.

- Sonicate it with methanol for 20 min.

- Dry it and put it back.

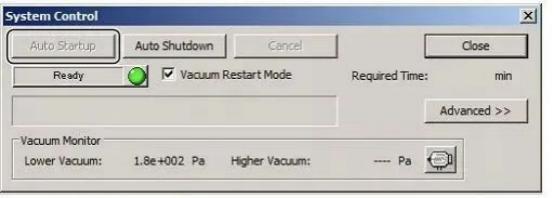

2. After shutting down the liquid phase, the mass spectrometer enters standby mode, opens the software “System Control” module, clicks on “Auto Shutdown,” and waits for the mass spectrometer heating module and the DL to cool down. Then the molecular turbine pump will shut down after the DL has cooled down, and the molecular turbine pump and the mechanical pump will stop. Wait until the shutdown is completed, close the software, and use the DL Plug to block the DL inlet.

3. Check the auxiliary system to turn off the power supply of the liquid chromatography units and the mass spectrometry unit; turn off the power supply of the nitrogen generator or the main gas valve of the liquid nitrogen tank and the main gas valve of the argon cylinder; empty the waste liquid and check the position of the waste gas pipe.

II. Resume the use of the operation

1. Turn on the power supply of the hardware and turn on the power switch of the liquid chromatography units, the mass spectrometry mainframe, and the computer in turn, and observe that the green indicator light of the liquid chromatography units lights up in turn and the “STATUS” indicator light of the mass spectrometry mainframe lights up.

2. Turn on the gas source and open the main gas valve of the argon cylinder and the main gas valve of the nitrogen generator or liquid nitrogen tank. Check the gas output pressure of the nitrogen and argon cylinders (nitrogen pressure-reducing valve gauge reads 690-800 kPa, argon pressure-reducing valve gauge reads 500 kPa).

Start LabSolutions, click on the “Main” button on the left-hand side of the window, then click on the “System Control” button at the bottom left-hand side of the window, click on the Click on “Advanced” button and press the “Open” button on the right side of the CID GAS to open the collision gas.

3. In the “System Control” module, click on “Auto Startup” the mechanical pump and the molecular turbine pump will start and wait for the vacuum to stabilize (12 hours or more is recommended). )

4. System flushing

① Replace the mobile phase line carrying the aqueous phase with ultrapure water, the needle wash line with 50% methanol aqueous solution, and the plunger cleaning line with 10% isopropanol aqueous solution. The mobile phase line was exhausted for 5 minutes, and the autosampler line was exhausted for 25 minutes.

② Flush the chromatography system for 60 minutes using a flow rate of 0.4 mL/min and 50% methanol.

③Pull out the DL tube plug.

④Prepare the mobile phase according to the experimental conditions to be performed, place the prepared mobile phase on the instrument, perform the mobile phase line venting operation, confirm that the column is properly installed in the column temperature chamber, recall the method file, start the liquid chromatography and mass spectrometry units and perform method equilibration.

Thermo Fisher Part

I. Scope: ISQ EC/EM Single Quadrupole LCMS shutdown procedure.

1. Before shutting down, flush the system with a salt-free mobile phase (LCMS grade required as a minimum) to ensure that the mass spectrometer’s sample components, column effluent, and buffer salts are thoroughly flushed out.

2. Set the vaporizer temperature to zero.

3. Turn off the pump flow rate into the mass spectrometer and purge with nitrogen for more than 5 min.

4. Set Sheath gas pressure, Axu gas pressure, and Sweep gas pressure to zero in the software.

5. Turn off the nitrogen cylinder regulator valve or the generator switch.

6. Turn off the ISQ main power switch.

7. Double-check that the water, electricity, and gas are turned off and empty the waste liquid.

II. Application: LCQ/LTQ series ion trap liquid mass spectrometer shutdown steps.

1. At the end of the experiment, remove the column, connect the two passes and rinse the sample transfer Peek tube and ion source (ESI and APCI). The rinsing procedure is as follows.

- Set the ion transfer capillary temperature to 200 °C.

- Plug the ion transfer capillary with a high-temperature resistant spacer or APCI discharge pin.

- Set the spray voltage of the ESI to 0 (if the APCI source is set to 0 for the discharge current).

- Set the sheath gas to a flow rate of 30.

- Set the auxiliary gas flow rate to 5.

- Set the ion source temperature to 500°C. (No need to set this for ESI without heating)

- Rinse with a liquid phase pump delivering 50:50 methanol: water for at least 15 minutes at a flow rate of approximately 0.5 mL/min.

- Turn off the flow rate and purge with nitrogen for 5 minutes.

- Switch the status of the mass spectrometer to Standby mode in the Tune software.

III. Scope of application: TSQ Series Triple Quadrupole Liquid Mass Spectrometer Shutdown Procedure.

1. At the end of the experiment, remove the HPLC column, connect the unions and rinse the sample transfer PEEK tube and ion source (ESI and APCI) with the following rinsing procedure.

- Set the ion transfer capillary temperature to 200 °C;

- Plug the ion transfer capillary with a high-temperature resistant spacer or APCI discharge pin;

- set the ESI spray voltage to 0; (if the APCI source is set to 0 for discharge current)

- Set the sheath gas to a flow rate of 30;

- Set the auxiliary gas flow rate to 5.0

- Set the ion source temperature to 500°C; (no need to set this for ESI without heating function)

- Flush with liquid phase pump 50:50 methanol: water for at least 15 minutes at a flow rate of approximately 0.5 mL/min;

-Turn off the flow rate and purge with nitrogen for 5 minutes;

- Switch the status of the mass spectrometer to Standby mode in the Tune software.

2. Turn off the Electronics Service Switch. 3.

3. Turn off the Vacuum Switch after one minute (skip this step for instruments outside the Quantum range).

4. Simultaneously turn off the Main Power Switch to the mass spectrometer’s Off (O) position.

5. Turn off the power switch for the liquid phase section.

6. Turn off the computer.

7. Turn off the UPS power supply and close the main nitrogen and argon cylinder valves and the pressure divider.

IV. Scope of application: QE Series High-Resolution Liquid Mass Spectrometer QE Focus/QE/QE Plus/QE HF/QE HFX Shutdown procedure.

1. At the end of the experiment, remove the column, connect the HPLC unions and rinse the sample transfer peek tube and ion source (ESI and APCI) with the following rinsing procedure.

- Set the ion transfer capillary temperature to 200 °C;

- Plug the ion transfer capillary with a high-temperature resistant spacer or APCI discharge pin;

- Set the spray voltage of the ESI to 0 (if the APCI source is set to 0 for the discharge current);

- Set the sheath gas to a flow rate of 30;

- Set the auxiliary gas flow rate to 5.0

- Set the ion source temperature to 500°C; (no need to set this for ESI without heating function)

- Flush with liquid phase pump 50:50 methanol: water for at least 15 minutes at a flow rate of approximately 0.5 mL/min;

- Turn off the flow rate and purge with nitrogen for 5 minutes;

- Switch the status of the mass spectrometer to Standby mode in the Tune software. 2;

2. Turn off the Electronics Service Switch.

3. After one minute, turn off the Mass Spectrometer Main Power Switch to the Off (O) position.

4. Turn off the computer.

5. Turn off the UPS power supply, and after 15 minutes, turn off the nitrogen cylinder main valve and pressure divider. Note: Do not leave any solvent residue in the liquid phase column temperature chamber. Wipe dry (to prevent solvent from evaporating and triggering the gas humidity alarm) and empty the waste bottle of waste liquid.

Content source: Shimadzu, Thermo Fisher, AB, Waters, etc.

Post time: Jan-21-2023